应用中心

News Information

新型安瓿封口机A-10提高了处理稀释化学试剂溶液的安全性

文/ 发布于2020-11-19 浏览数量:

The Edgewood Chemical Biological Laboratory (ECBC) recently acquired a new machine that improves the efficiency and safety in processing orders of dilute chemical agents used for research and testing.

埃奇伍德化学生物实验室(ECBC)最近获得了一种新机器,可以提高用于研究和测试的稀释化学制剂处理订单的效率和安全性。

Brandon Bruey, chemist at ECBC’s Chemical Transfer Facility (CTF), said the dilute samples contain a high-purity sample of chemical agent dissolved in solvent that has been analyzed and certified so that other research labs know what concentration with which they are working.

ECBC化学转移设施(CTF)的化学家布兰登·布鲁伊(Brandon Bruey)说,稀释样品中含有溶解在溶剂中的高纯度化学试剂样品,这些样品已经过分析和认证,以便其他研究实验室知道它们的工作浓度。

He added that most customers utilize the dilute agent solutions as standards to ensure they can identify and quantify chemical agent material on analytical instrumentation.

他补充说,大多数客户使用稀释剂溶液作为标准,以确保他们能够识别和量化分析仪器上的化学试剂材料。

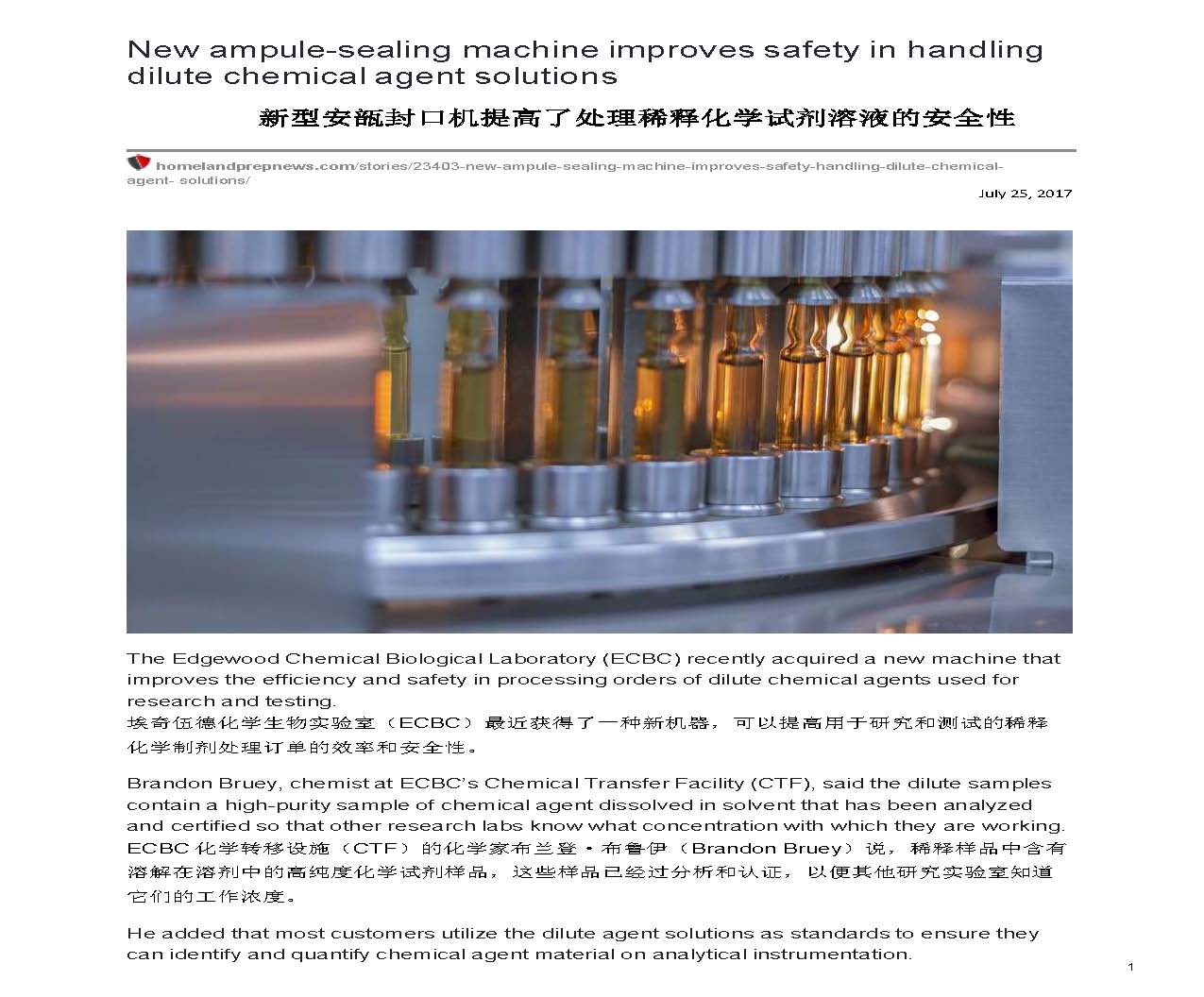

After dilute solutions are certified by ECBC, they must be injected into open-ended glass ampules, which are heat-sealed closed for safe transport and handling. Until recently, each ampule had to be sealed using a hand torch and glass rod, which, according to Bruey, was a time-consuming and labor intensive process.

稀释溶液经ECBC认证后,必须注入开放式玻璃安瓿中,瓶口玻璃瓶盖应热封,以确保安全运输和搬运。直到最近,每个安瓿都必须用火焰喷枪和玻璃棒密封,据布鲁伊说,这是一个耗时费力的过程。

ECBC’s CTF will now use a new bench-scale ampule sealer that automatically closes each vial. First, the ampules are loaded onto a circular carousel, which individually pass in front of a fixed torch. The machine then evenly melts glass seals without the issues seen with hand- sealing, such as glass bubbles or leaky vials.

ECBC的CTF现在将使用一种新的台式安瓿封口机,自动熔封每个小瓶。首先,安瓿被装载到一个圆形样品载具上,旋转载具盘在一个固定的火焰喷头前面轮换传递小瓶。然后机器均匀地熔化玻璃密封件,而不会出现手工密封时出现的问题,例如玻璃气泡或玻璃瓶泄漏。

“This gives every one of our vials a uniform seal and speeds up the process immensely,” Bruey said.

布鲁伊说:“这使我们的每一个小瓶都有一个统一的密封,大大加快了这个过程。”。

According to ECBC, the new machine provides consistent heating with a gas mixture of oxygen and propane that is control to ensure the best flame temperature.

根据ECBC的说法,这台新机器提供持续加热的氧气和丙烷混合气体,这是控制,以确保最佳火焰温度。

“Once the flame temperature and weld times are set, the ampule sealer will produce a more uniform seal for all ampules,” Bruey said. “It takes human error out of the equation.”

布鲁伊说:“一旦火焰温度和焊接时间设定好,安瓿封口机将为所有安瓿生产更均匀的密封。”。“它将人为错误排除在等式之外。”

While the machine does ensure a safer process, it still takes a team of four to complete a production run — one to fill ampules, one to operate the ampule sealer, one to ensure vials are fully sealed, and one to correctly label each ampule.

虽然这台机器确实确保了一个更安全的过程,但仍然需要一个四人小组来完成生产运行——一个负责灌装安瓿,一个操作安瓿封口机,一个确保小瓶完全密封,一个负责正确标记每个安瓿。